SM2XJP went down with the tower section me and SM2UVU fixed to get it galvanized. A company Gallac in Skellefteå who has got a big factory said no to the job. So I called a company called Galvpart in Vännäs who are a lot smaller but they accepted the job for a very fair price. The problem is that they need to remove all zink from the old section before they can put it into one of the bath needed before the actual galvanization. However Gallac said they did not have a big enough room for the 6m section since their bath is only 5m long. However Galvpart have an even smaller bath which is 2m long but they managed to fix it anyway 🙂 By Thursday they had it done so SM2XJP went the 250km roundtrip today and picked up the parts.

SM2LIY helped me previously this week to pour the concrete for the pillar. It contains about 600l of concrete so it was very nice having Per getting water when we ran out of it and also “stomping” the concrete to get rid of air. He did an excellent job so the foundation turned out great.

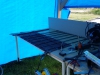

We got to borrow the L70 from GTL (local company) which SM2XJP drove and fixed the ground around the foundation. He also did change the angles a bit around the military towers foundation since water was gathering around the foundation instead of pouring away. We also got rid of all old insulation material from the house which was great and the tower sections were moved into place so we don’t need to carry them so far.